Our team consists of university students who, in addition to their studies, expand their knowledge and experience with our unique project. A little bit more than 40 members work in our six departments every day to achieve our goals. The work of the departments is closely related to each other, so it is important to have proper and precise communication to ensure that the processes run smoothly.

Leadership

Management

The primary goal of our department is to support the construction side. Our work includes ordering management, sponsorship contact, and financial management. In addition, our department is responsible for all kinds of communication, event organization, HR-related administration and other projects.

Design

The Design department is responsible for the design of all the components that go with the engine and the testbench. We then run various finite element and life simulations on the components. If they pass these tests, once the technical documentation has been drawn up, we turn to our manufacturing support staff, who produce our designs on short deadlines and to an impeccable quality.

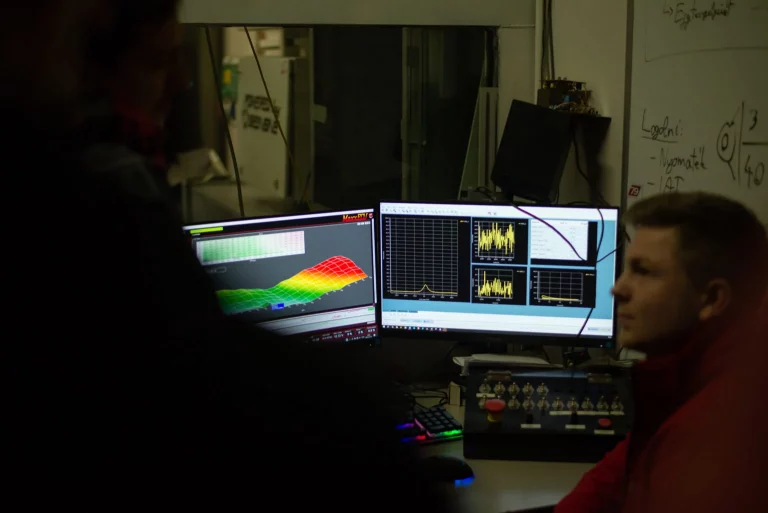

Testbench

Our department is dedicated to unlocking the power of our engine with new engine controls optimised for specific components. Calibration and validation are carried out on our engine brake bench, designed, built and operated by us, which is an exceptional situational advantage for us as no other European team has its own brake bench. In addition, the application plays an important role for us, which allows us to keep the lifetime of our engine at the same time as the increased performance. During the races, we are responsible for analysing the engine data, so we are active participants in the test days and races.

Hybrid powertrain development

Since its inception (2021), our department has recently made progress on the first hybrid drive for SZEngine. Our goal is to have a working hybrid system in a test car and later in a Formula Student compliant race car. According to the rules, a maximum voltage of 60V (DC) can be used to power a hybrid battery with a maximum capacity of 500Wh, with a maximum total weight of the active electrical energy storage units not exceeding 3 kilograms. Our concept is based on a hybrid system with an internal combustion engine driving the rear axle and a supplementary electric drive on the front axle of the car. In addition to gear-driving the electric motors, torque vectoring must also be implemented to get the best possible cornering speed and acceleration out of the car. The department’s tasks therefore include the mechanical implementation of the drive and components, the design of the electronic components and network, the design and implementation of the battery and engine cooling, and the calculation and optimisation of the electric drive system to work in harmony with the internal combustion engine.

Development

In the development department, we deal with the thermal, flow and other thermodynamic aspects of our racing engine. Our tasks include the design and optimisation of intake and exhaust systems. In 2023/24, a turbocharged engine has been added to our engine generation range, the thermodynamic processes of which have been calculated on the basis of programs used in industry. In the coming years, the department also aims to design custom cylinder heads for control, intake ports and combustion chamber optimisation.

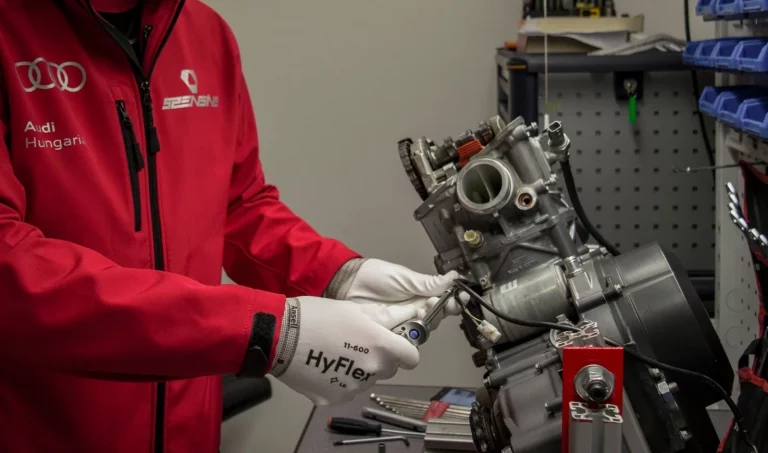

Test

The main task of our department is the assembly of engines and auxiliary equipment, ensuring their race-ready condition. We also deal with the application of new parts and their testing, the design and evaluation of car tests